Bowling, a timeless sport enjoyed by millions around the globe, has captured the hearts of enthusiasts for centuries. As you step up to the lane, clutching that perfectly polished bowling ball, have you ever wondered about the secrets hidden within its sleek exterior?

Is it hollow, filled with a mysterious void, or is there more to it than meets the eye? In this comprehensive article, we’ll delve deep into the anatomy of a bowling ball, debunking the common myth about whether they are hollow or solid, and unraveling the ingenious engineering that makes these spherical marvels perform flawlessly on the lanes.

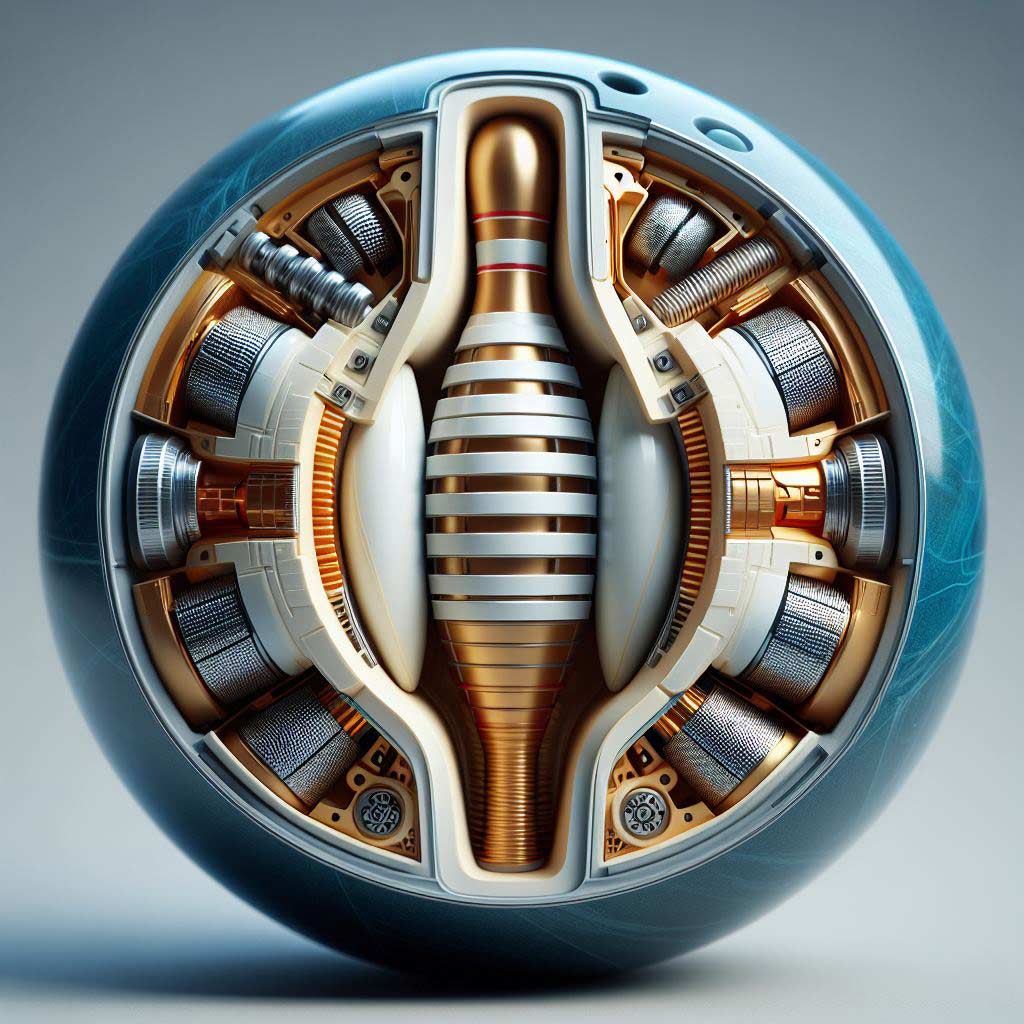

The Anatomy of a Bowling Ball

At first glance, a bowling ball may appear to be a simple, solid sphere, but its construction is a masterpiece of precision and design. At its core (literally), lies the heart of the ball, typically made of dense materials like polyester or urethane. This core plays a crucial role in determining the ball’s overall weight distribution and reaction on the lane.

The core is the foundation upon which the rest of the ball’s components are built. Its density and shape contribute significantly to the ball’s overall dynamics, including its rev rate, flare potential, and backend motion. Manufacturers carefully engineer the core to achieve specific performance characteristics, catering to different playing styles and lane conditions.

Surrounding the core is the coverstock, the outer shell of the ball. This layer is available in various materials, such as reactive resin, plastic, or urethane, each designed to perform optimally under different lane conditions. The coverstock not only protects the inner components but also influences the ball’s traction, hook potential, and overall performance.

Reactive resin coverstocks, for instance, are known for their aggressive traction and hook potential, making them ideal for bowlers who prefer a high rev-rate style or those playing on heavily oiled lanes. Plastic coverstocks, on the other hand, offer a smoother and more controlled reaction, suitable for drier lane conditions or bowlers seeking a straighter ball path.

But the engineering marvel doesn’t stop there. Within the ball’s interior, weight blocks are strategically placed to achieve the desired balance and reaction on the lane. These weights, often made of dense materials like tungsten or bismuth, are carefully positioned to optimize the ball’s dynamics, ensuring consistent and predictable shots.

The placement of weight blocks plays a crucial role in determining the ball’s track flare (the amount of side roll or rev rate) and overall balance. By distributing the weight strategically, manufacturers can create balls that hook more aggressively or roll straighter, catering to different playing styles and lane conditions.

The Myth of Hollow Bowling Balls

Despite the intricate design and construction of bowling balls, a persistent myth has circulated among some circles – the belief that bowling balls are hollow.

This misconception may have arisen due to the balls’ relatively lightweight nature or perhaps the manufacturing processes involved. However, the truth is that bowling balls are, in fact, solid and not hollow.

Debunking this myth is crucial for understanding the true essence of bowling ball performance. A hollow construction would compromise the ball’s ability to transfer energy efficiently, resulting in unpredictable and inconsistent shots.

Additionally, the structural integrity of a hollow ball would be compromised, rendering it susceptible to damage and reducing its longevity on the lanes.

Imagine a hollow bowling ball colliding with the pins – the impact would be severely diminished, and the energy transfer would be inefficient, leading to reduced pin-carrying power and unpredictable ball motion.

Furthermore, the lack of structural reinforcement within a hollow ball would make it prone to cracking or deformation over time, drastically reducing its lifespan.

Reasons for a Solid Construction

The solid construction of bowling balls is not merely a design choice; it is a necessity driven by performance, durability, and precision. Here are some key reasons why bowling balls are engineered as solid spheres:

Performance:

A solid construction allows for optimal energy transfer from the ball to the pins, ensuring maximum striking power and consistent ball reaction.

The dense materials used in the core and weight blocks contribute to this energy transfer, enabling the ball to maintain its momentum and trajectory throughout the shot.

When a solid bowling ball strikes the pins, the kinetic energy is efficiently transferred, resulting in a powerful impact that can knock down even the most stubborn pin formations. This energy transfer is critical for achieving consistent strikes and spares, which are the ultimate goals in any bowling game.

Durability:

Bowling balls endure repeated impacts against the lane surface and pins, subjecting them to immense stress. A solid construction reinforces the ball’s structural integrity, preventing deformation and ensuring longevity. The dense materials used in the core and coverstock also help resist wear and tear, prolonging the ball’s lifespan.

Imagine if bowling balls were hollow – the repeated impacts would cause the outer shell to flex and deform, leading to cracks and eventually compromising the ball’s performance and safety. The solid construction mitigates these risks, allowing bowling balls to withstand the rigors of the game for years to come.

Weight distribution:

The strategic placement of weight blocks within a solid ball allows for precise weight distribution and balance. This balance is crucial for achieving the desired hook potential and ensuring that the ball travels smoothly and accurately down the lane. Without a solid construction, achieving this level of precision would be impossible.

By strategically positioning the weight blocks, manufacturers can create bowling balls that hook more aggressively or roll straighter, catering to different playing styles and lane conditions. This level of customization is only possible with a solid construction, where the weight can be precisely distributed throughout the ball’s interior.

The Evolution of Bowling Ball Materials

The quest for improved bowling ball performance has driven the evolution of materials used in their construction. In the early days, bowling balls were crafted from traditional materials like rubber and plastic, which provided decent performance but had limitations in terms of reaction and durability.

However, with advancements in materials science and technology, modern bowling balls have undergone a remarkable transformation. Reactive resin coverstocks, for instance, have revolutionized the game by offering increased traction and hook potential, allowing bowlers to impart more revolution on the ball for greater pin-carrying power.

These reactive resin coverstocks are formulated with advanced polymers and additives that enhance the ball’s grip on the lane surface, especially in oily conditions.

As the ball transitions from the oiled heads to the drier backends, the coverstock material helps generate more traction and hook, resulting in a more powerful and predictable ball motion.

Furthermore, particle composites and other advanced materials have been introduced into bowling ball cores, providing enhanced weight distribution and optimized dynamics.

These materials, combined with precision engineering and manufacturing processes, have enabled the creation of highly specialized bowling balls tailored to specific lane conditions and playing styles.

For example, asymmetric cores with strategically placed weight blocks can promote increased flare potential and backend motion, while symmetric cores offer a more predictable and controlled ball reaction.

By combining these core designs with the right coverstock material, bowlers can fine-tune their equipment to match their individual playing styles and preferences.

The role of technology in developing advanced bowling ball materials and designs cannot be overstated. Computer simulations, 3D modeling, and finite element analysis have allowed manufacturers to fine-tune every aspect of a bowling ball’s construction, from the core design to the coverstock formulation, ensuring optimal performance and consistency.

Choosing the Right Bowling Ball

With the vast array of bowling ball options available in today’s market, selecting the perfect ball can be a daunting task. However, by considering a few key factors, you can increase your chances of finding the ideal match for your playing style and preferences.

Weight:

The weight of a bowling ball is a crucial consideration, as it impacts your ability to generate power and control. Heavier balls (up to the maximum allowed weight of 16 pounds) generally provide more striking power but may be more challenging to control for some bowlers. Conversely, lighter balls may offer better control but sacrifice pin-carrying potential.

It’s essential to find the right balance between weight and control that suits your physical abilities and playing style. Experienced bowlers often recommend starting with a ball weight around 10% of your body weight and adjusting from there based on your comfort level and ball reaction.

Coverstock material:

The material used for the coverstock significantly influences the ball’s traction and reaction on the lane. Reactive resin coverstocks are known for their aggressive traction and hook potential, making them suitable for bowlers who prefer a high rev-rate style.

Plastic or urethane coverstocks, on the other hand, offer a smoother and more controlled reaction, ideal for bowlers seeking a straighter ball path or playing on drier lane conditions.

Understanding the characteristics of different coverstock materials can help you make an informed decision based on your playing style and the lane conditions you typically encounter.

Core design:

The core design plays a pivotal role in determining the ball’s overall dynamics and reaction. Asymmetric cores, for instance, can promote increased flare potential and backend motion, while symmetric cores offer a more predictable and controlled ball reaction.

High-performance bowlers often favor asymmetric cores for their increased backend motion and flare potential, allowing for more aggressive hooking action on the lanes.

On the other hand, symmetric cores are a popular choice for bowlers seeking a more controlled and predictable ball reaction, making them ideal for those who prefer a straighter ball path or are still developing their rev rates.

Personal playing style:

Ultimately, the choice of bowling ball should align with your personal playing style and skill level. For example, more aggressive or high rev-rate players may benefit from balls with reactive resin coverstocks and asymmetric cores, while bowlers seeking a more controlled and straight ball path may prefer plastic or urethane coverstocks with symmetric cores.

Additionally, bowlers who frequently encounter heavy oil patterns on the lanes may gravitate towards aggressive balls with ample traction, while those playing on drier lanes might prioritize control over hooking action.

Proper drilling and layout:

Even with the perfect ball, improper drilling and layout can significantly impact performance. It’s essential to work with a professional ball driller who can analyze your release, rev rate, and playing style to determine the optimal drilling pattern and layout for your ball. This customization ensures that the ball’s weight distribution and dynamics are optimized for your specific needs.

The drilling layout encompasses factors such as the placement of the finger holes, the position of the pin (or slugs), and the overall weight distribution across the ball’s surface.

These elements can be fine-tuned to promote the desired ball motion, whether it’s increased length, earlier revs, or a smoother transition through the backends.

By working closely with an experienced ball driller, you can maximize the potential of your bowling ball, ensuring that its construction and layout work in harmony with your individual technique and preferences.

Conclusion:

As we’ve explored in depth, the myth of hollow bowling balls has been resoundingly debunked. These spherical wonders are meticulously engineered as solid constructions, with intricate cores, coverstocks, and weight blocks working in harmony to deliver unparalleled performance on the lanes.

The solid construction not only ensures optimal energy transfer and consistent reaction but also provides the durability and longevity that bowling enthusiasts demand.

As materials science and manufacturing technologies continue to advance, we can expect even more innovative and high-performing bowling ball designs to emerge, pushing the boundaries of what’s possible in this beloved sport.

When selecting your next bowling ball, remember to consider factors such as weight, coverstock material, core design, and personal playing style.

Don’t hesitate to consult with professionals to ensure proper drilling and layout, as this customization can unlock the full potential of your equipment and elevate your game to new heights.

So, the next time you step up to the lane, clutching that perfectly crafted bowling ball, remember the ingenious engineering that lies within. Embrace the solid construction, experiment with different materials and designs, and find the perfect ball that complements your playing style and takes your game to new heights.

In the world of bowling, the solid construction of balls is not just a necessity – it’s the foundation upon which countless strikes, spares, and cherished memories are built. With each roll, you’re engaging in a testament to human ingenuity and the relentless pursuit of perfection in this timeless sport.